Impinging Jet Heat Transfer Analysis

Aug 2025 - Dec 2025

This project involved using CFD methods to analyze how different factors, such as pipe diameter and Nusselt Number, affect the boundary layer and flow through a copper pipe onto a heated copper plate.

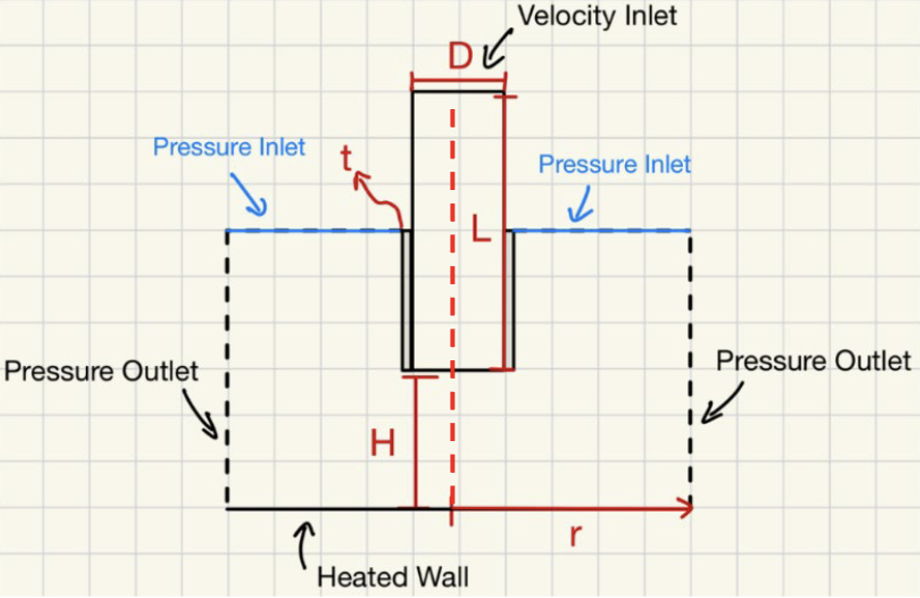

Setup

Impinging jets are high-velocity flows that strike a surface perpendicularly and are used in applications such as turbine blade cooling, aircraft de-icing, and material processing. However, physical experiments are often expensive and time-consuming, making computational fluid dynamics (CFD) an efficient alternative for modeling their behavior.

For this project, Mariana and her teammates used ANSYS Fluent to simulate multiple impinging jet cases with varying Reynolds numbers and pipe diameters. The simulations employed a 2D axisymmetric, steady-state Navier–Stokes model with the energy equation included, and a heated bottom wall maintained at 300.15 K.

Impinging Jet Geometry Sketch

GIF source: ANSYS Innovation Space, 2025. Used for educational visualization.

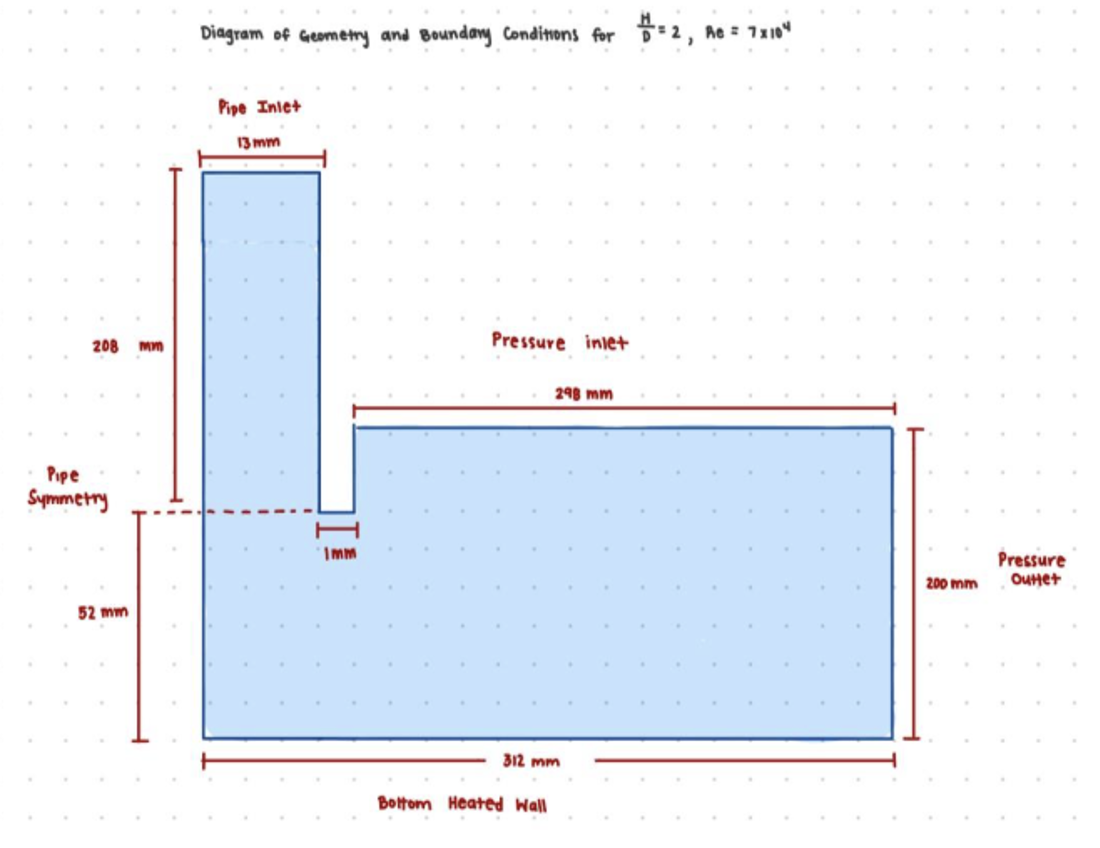

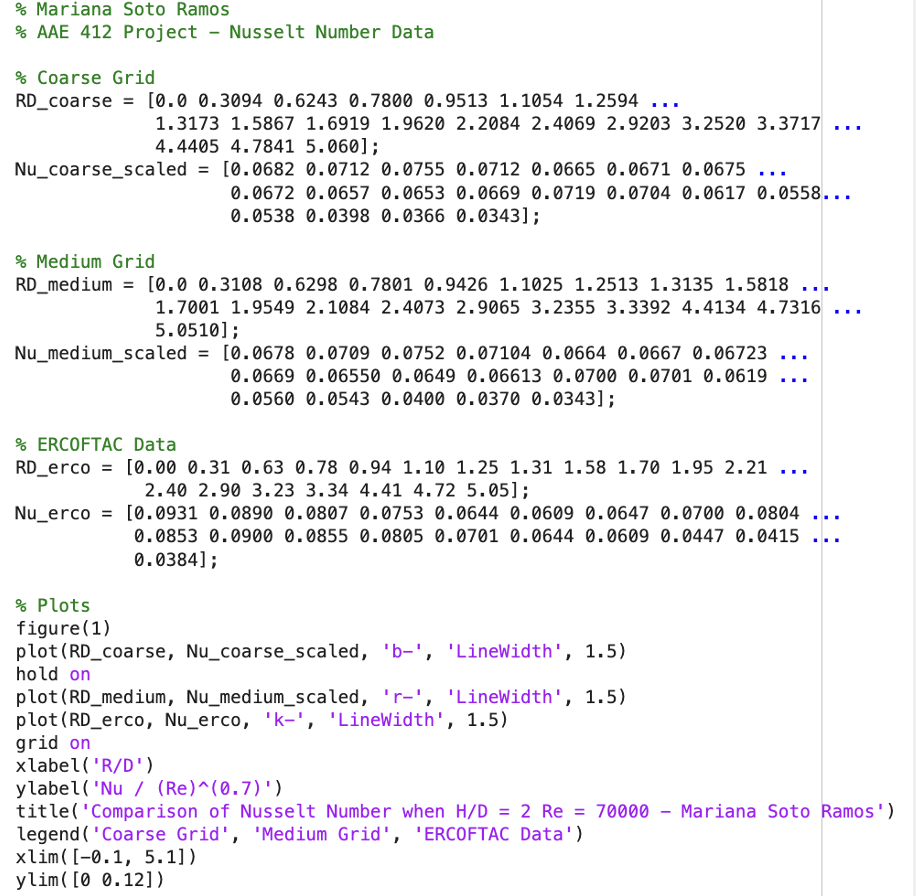

For her case, Mariana used an height-to-diameter (H/D) ratio of 2 and a Reynolds number of 70,000. Throughout her project, she made a coarse and refined grid to compare the resulting behavior.

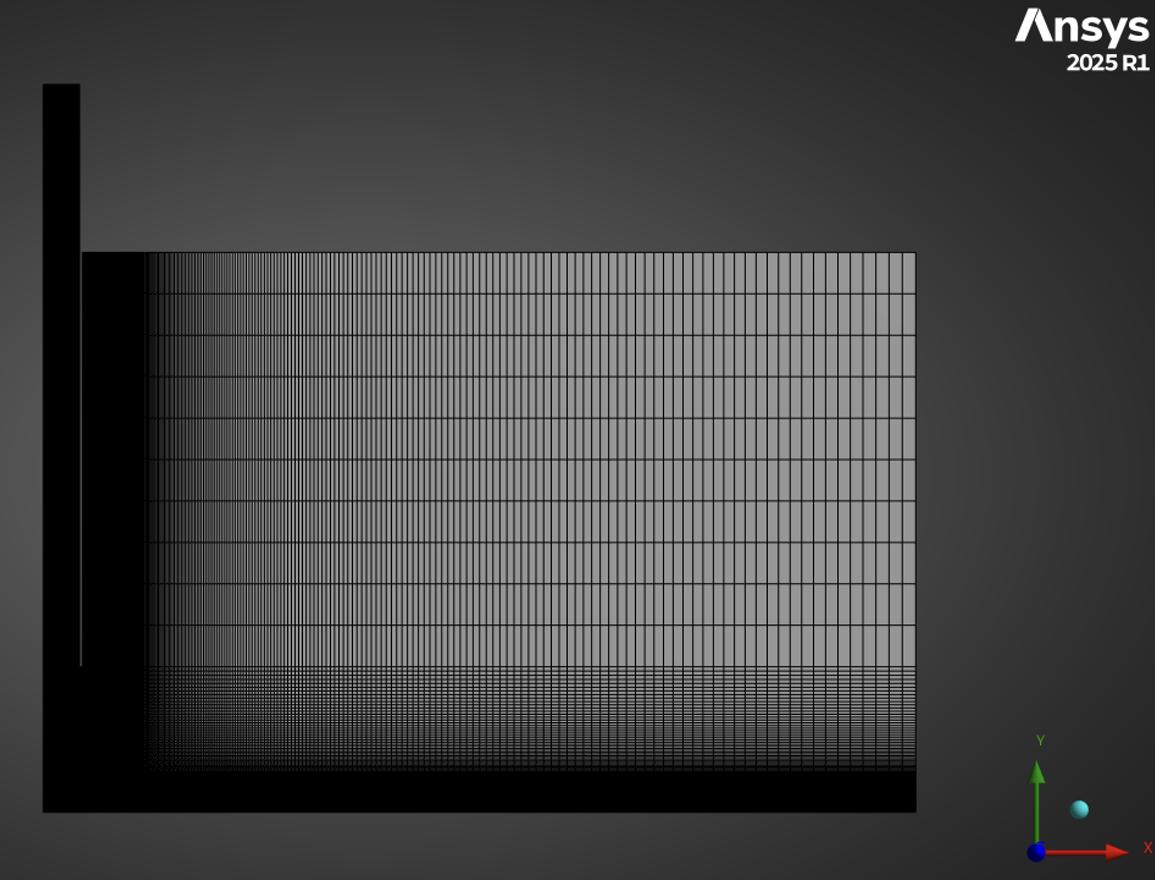

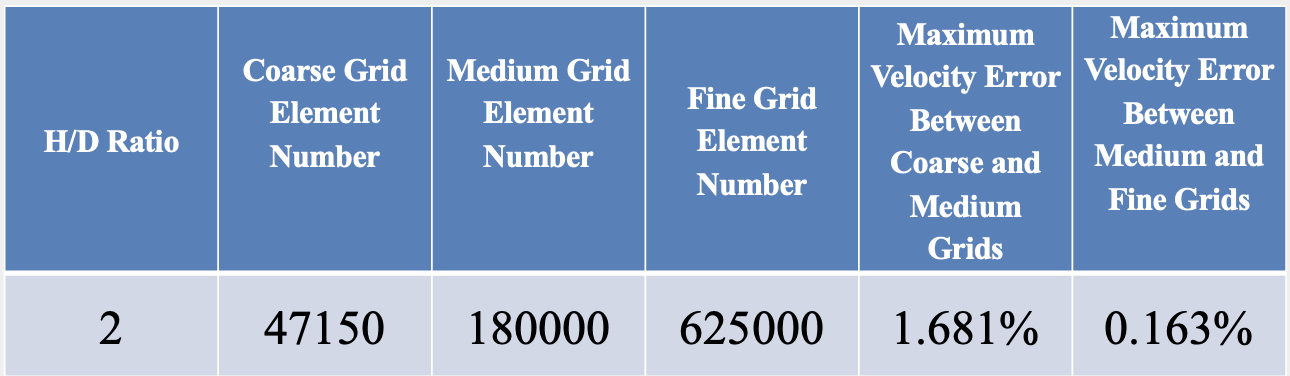

For her coarse mesh, Mariana’s grid had about 50,000 elements. The medium grid used about 180,000 elements. A fine grid was later employed, with 625,000 elements.

Meshing

Geometry Sketch

Geometry Coase Grid Mesh

Simulation

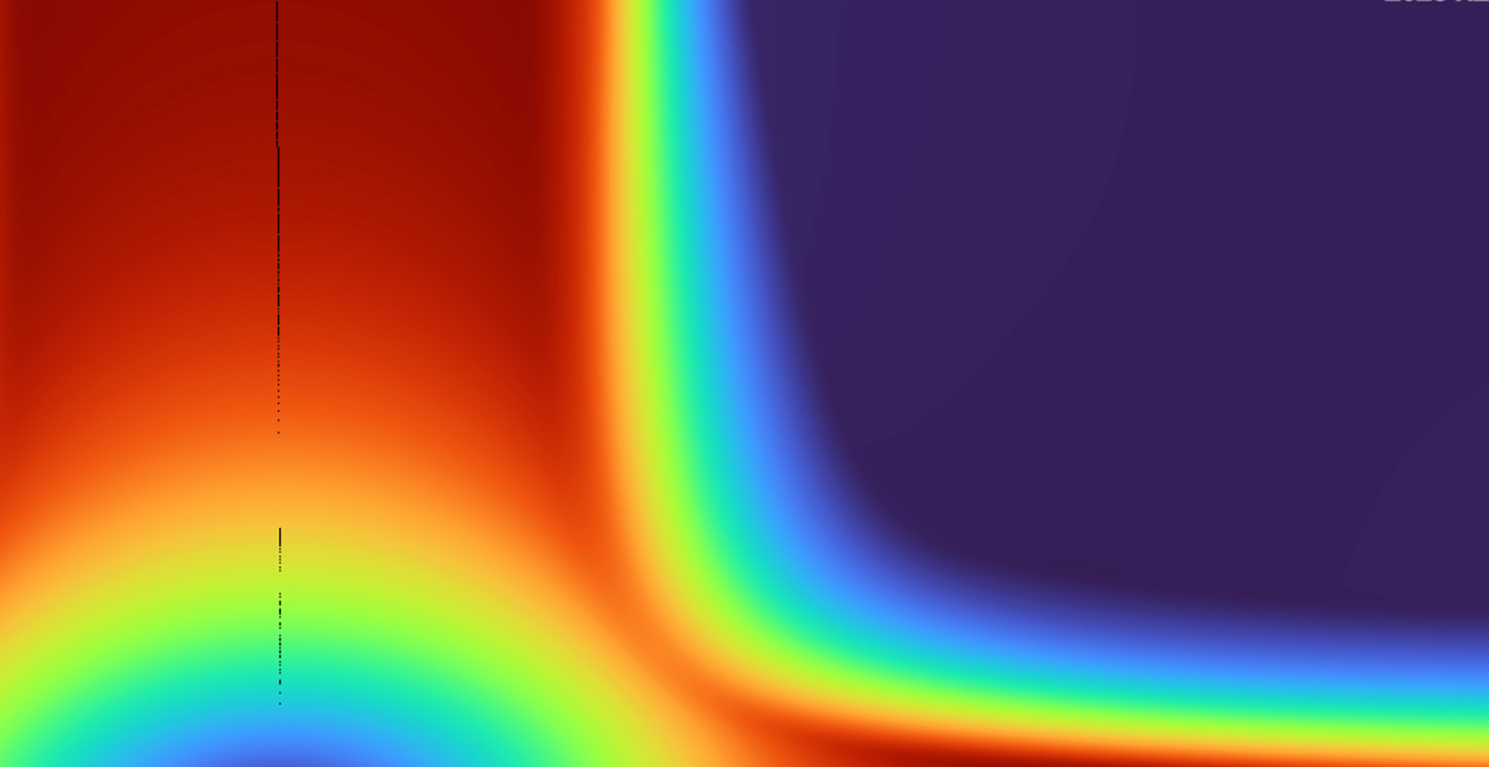

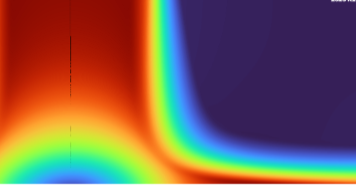

Velocity Contour Plot (Zoomed In)

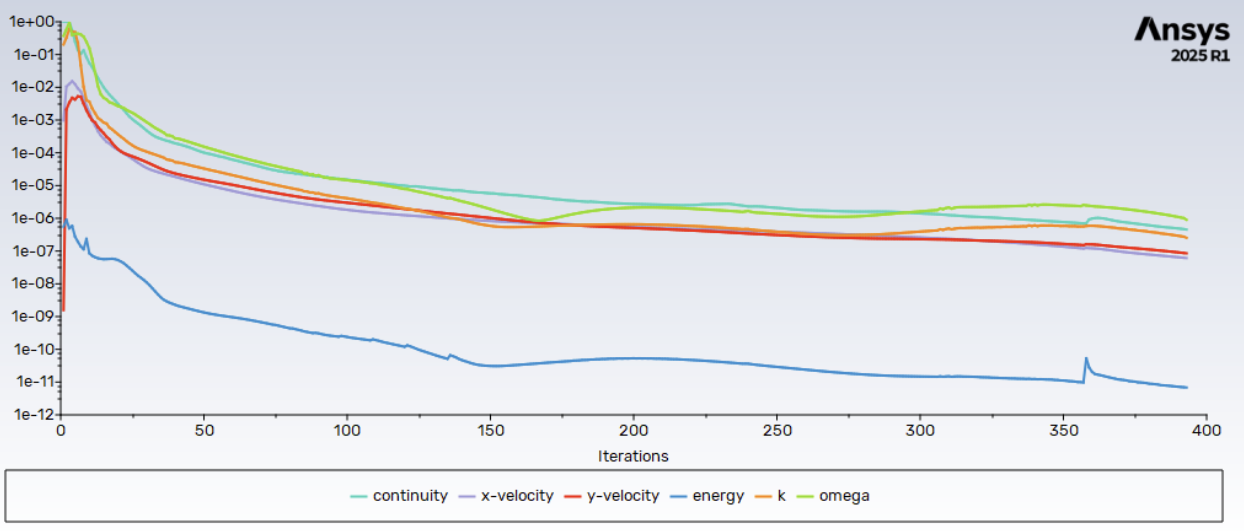

Simulation Residuals

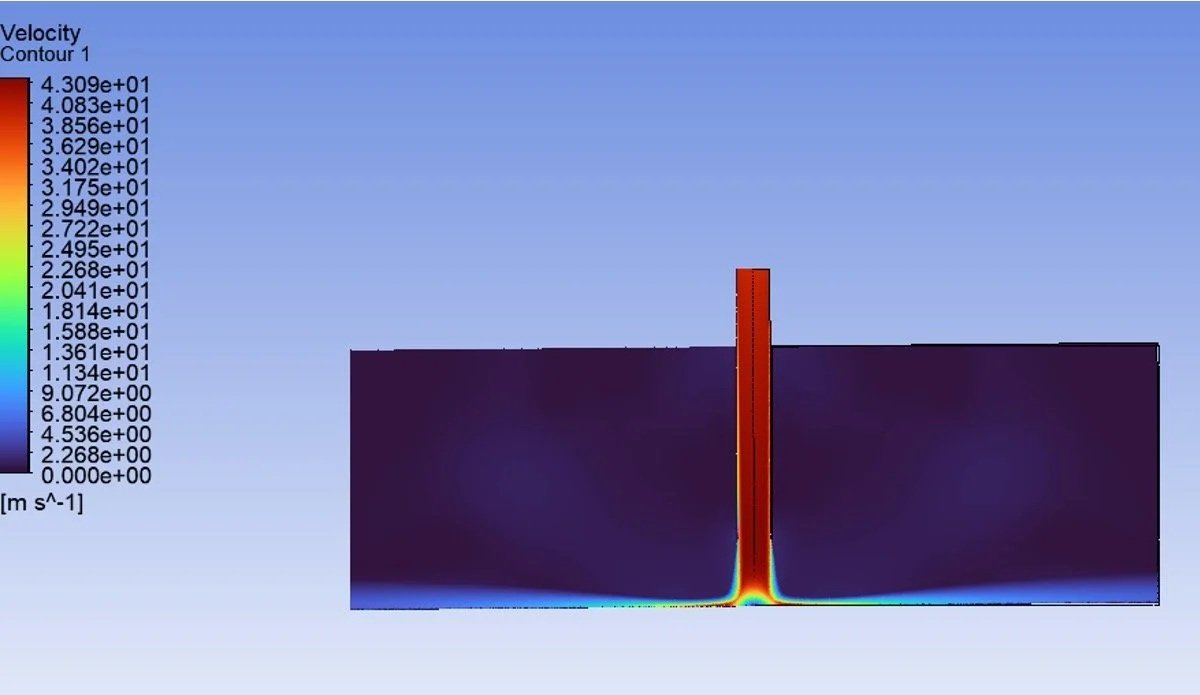

Velocity Contour Plot

The simulation was set to converge at a residual value of 1e-6, which was successfully achieved as shown in the plot on the left.

Velocity contours reveal that the high-velocity flow impinges on the plate almost immediately upon exiting the pipe, creating a sharply defined stagnation region. Additionally, the velocity smoothly decreases to zero along the heated wall, indicating that the mesh resolution is adequate for capturing the flow behavior.

Results

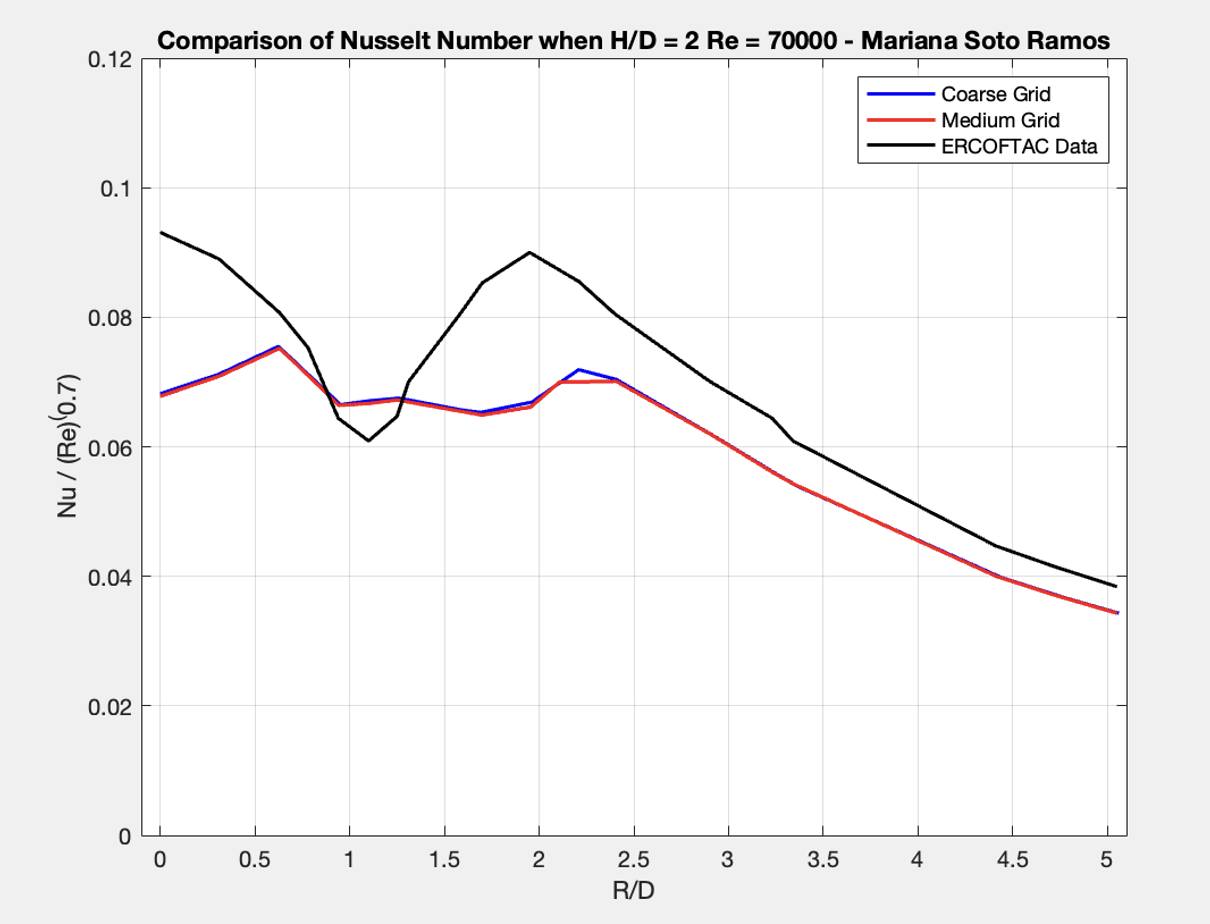

Using experimental data from the ERCOFTAC database, Fluent simulation results were scaled and plotted for comparison. The medium and coarse grids showed close alignment, indicating that further mesh refinement beyond the medium grid does not significantly impact the predicted heat transfer trends. However, the overall simulation underestimated the experimental values reported in the literature, despite exhibiting a similar trend.

Velocity differences between grids were quantified, revealing a 1.681% error between the medium and coarse grids, and a much smaller 0.163% error between the medium and fine grids. This suggests good grid convergence and that the medium grid provides a reasonable balance between accuracy and computational cost.